Projects

Dock 1 Line Cleaning: Possum Point Power Station - Dumfries, VA

Evacuated 73,500 gallons of contaminated water, light and heavy fuel oil.

Prepared abandoned fuel pipelines for demolition and removal.

Cleaned fuel pipelines of various sizes ranging from 3” to 24” in diameter. Each line was 800’ to 1000’ in length.

De-fueled and cleaned two loading arms that were part of the system.

Pipelines were cleaned by pigging and flushing methods.

Deployed and maintained 1500’ of 18” containment boom during the fuel removal process.

Boom was equipped with an anchoring system a and marker lights.

Cut and mechanically isolate abandoned lines from the active pier pipelines. Install blind flanges on active lines.

Pier location and appearance prior to start of Dumfries, VA project.

Containment boom deployment prior to the start of pipeline defueling

Strip insulation and begin bulk fuel oil removal process.

Pipeline pigging process.

Demolition process and final pier appearance after pipe removal complete.

Out-of-Service API-653 Inspections: Possum Point Power Station & Ladysmith CT Station

Two tanks per site. Four tanks total ranging in capacity from 1 million to 2.7 million gallons each with diameters from 60’ to 98’.

Product was diesel fuel.

Transfer 5.7 million gallons of fuel from tank to tank on site.

Transfer 1 million gallons to tanker trucks for transfer to other facilities.

Provided temporary pumping and filtering equipment for all fuel transfers.

All equipment was placed into secondary containment berms to contain any incidental leaks.

Mechanically isolated each tank by installing skillets so they were ready for entry by others.

Responsible for opening all manways and access covers, as well as, closing each cover at the conclusion of work in each tank.

Provided new gaskets and hardware for tank closure.

Observed and monitored tank re-filling process.

Provide confined space rescue standby services during all entry into the tanks for cleaning, blasting, coating, and repairs.

Performed work at both sites simultaneously.

Ladysmith tank-to-tank transfer

Ladysmith temporary tank-to-tank transfer system.

Possum Point temporary pump set up.

Drilling hole in center column to drain trapped fuel.

Out-of-Service API-653 Inspection: Chesterfield Power Station

One 12 million gallon tank in diesel fuel service.

Transferred 5 million gallons of fuel to a barge. Pier was approximately 2500’ away. Pumping took place 24 hours a day for 4 days.

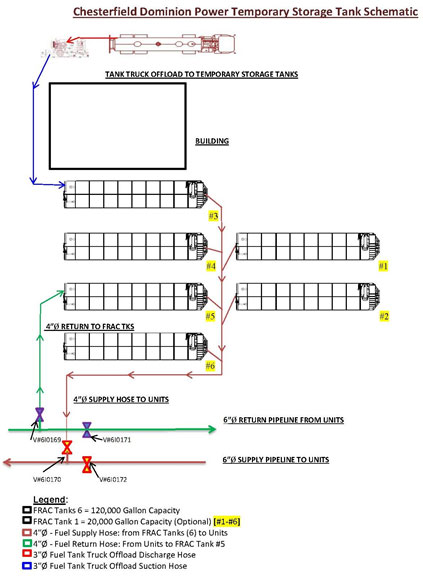

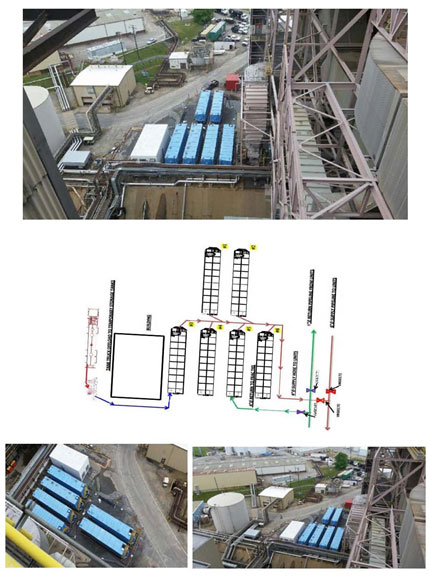

Set up and maintained a temporary tank storage system equipped with issue and return lines to supply the generation units with startup fuel while main fuel tank was out of service for inspection and repairs.

Incorporated a temporary truck offload station to replenish fuel in the temporary tanks as needed during the outage.

All equipment was placed into secondary containment berms to contain any incidental leaks.

Mechanically isolated the tank by installing skillets as needed for safe entry by others.

Responsible for opening all manways and access covers, as well as, closing each cover at the conclusion of work in the tank.

Provided new gaskets and hardware for tank closure.

Observe and monitor tank re-filling process.

Design of system implemented in the field.