- You are here:

- Home »

- In-Line Inspection (ILI) Support

In-Line Inspection (ILI) Support

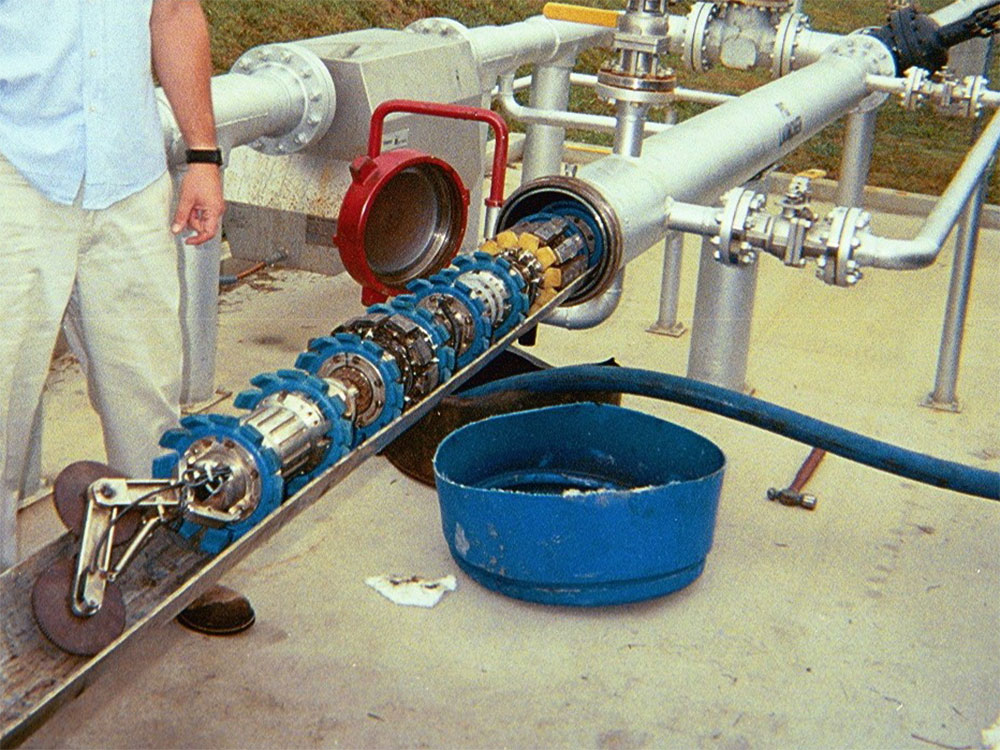

Preparation of an 6” MFL tool prior to another inspection run.

An important aspect of pigging services provided by PPSI is In-Line Inspection (ILI) support. This support includes onsite coordination with the in-line inspection tool vendor and support for launching, tracking, and retrieval of ILI tools. We also offer anomaly verification excavations after the completion of the ILI inspection as well as direct assessment (DA) excavations. All of the following support services are offered to the end client or to the ILI vendors themselves as a cost effective solution to experienced in-house cleaning, tracking, and verification crews.

- Preparatory pipeline survey to identify restrictive valves, mitered joints, and 1.5 D bends. Provide service to remove or correct such restrictions.

- Design, fabrication and installation of temporary launchers and receivers or retrofit existing traps to accommodate ILI tools.

- Pre-inspection pipeline cleaning and gauging.

- AGM selection, deployment, and monitoring.

- Geometry / Caliper tool launch and retrieval.

- ILI tool (MFL / UT) launch and retrieval.

- Tool tracking and location. (locally as well as cross country)

- Liquid batching for ILI tool flights.

- Installation of temporary tanks, pipes, hoses, and valves to facilitate product flow diversion.

- Temporary pump and storage tank solutions.

- Anomaly verification excavation and documentation.

- Rescue pigging and stuck tool retrieval utilizing highly sophisticated tracking equipment.

- Verification digs and verification.

- Anomaly location and GPS positioning.

- Pipeline GPS / GIS & mapping services.

- Additional solutions for unpiggable pipelines. (See Pipeline Pressure Testing & Inspections Page)

In addition, PPSI personnel has the field experience and knowledge to run ILI tools in the Type II and Type III hydrant loop systems utilized by the US Military for aircraft fueling.

Gauge plate tool from an 8” oily waste pipeline exhibiting some deflection from 1.5D bends.

Loading an 8” geometry tool for a 4.5 mile flight.

16” geometry tool positioned and ready to load into pig trap.

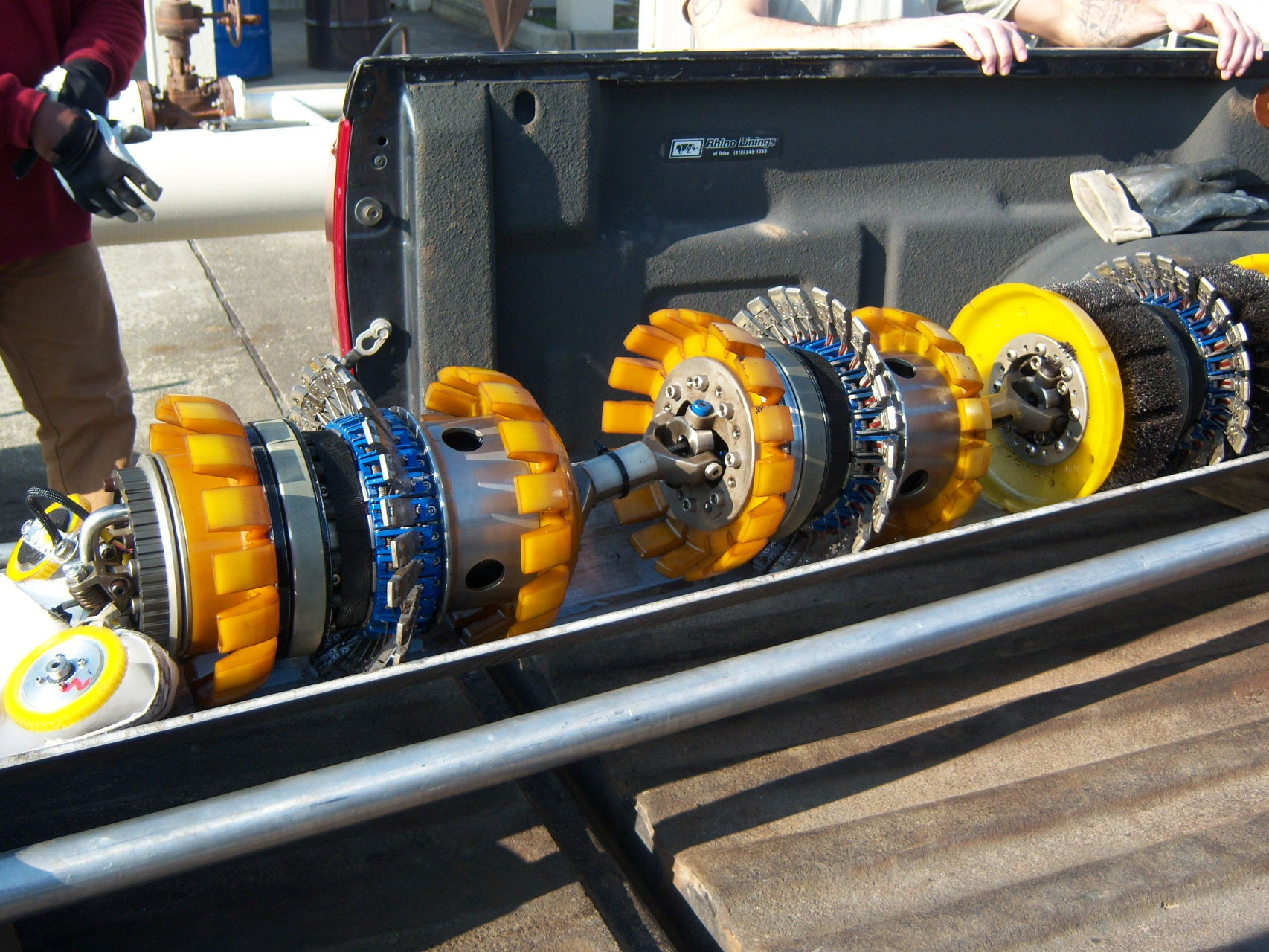

8” MFL tool post flight after a 8.5 mile flight.

Installation of a temporary trap prior to pigging at Elmendorf AFB, Alaska.

Temporary traps installed at Nellis AFB, Nevada.